Light industries Projects

Regina Pasta Factory

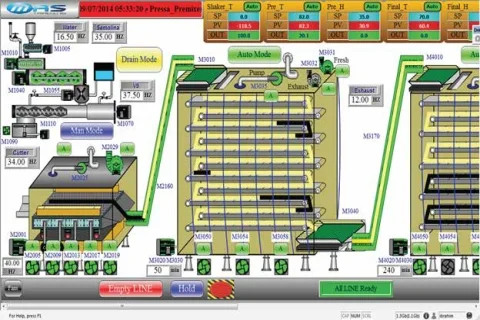

• Upgrade BUHLER production line for spaghetti pasta.

a- Supplying, Installing system for control, sensing temperature and moisture (Climate control).

b- Full SCADA system.

• Upgrade BUHLER production line for Short pasta:

a- Supplying, Installing system for control, sensing temperature and moisture (Climate control).

b- Full SCADA system.

EMA Pasta

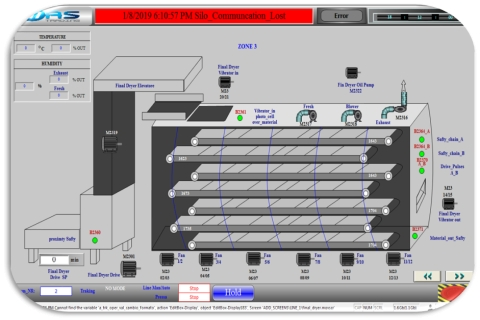

Design Power Panel for 34 Motors,9 Gates and 3 Hot Water Valves.

Design Control Panel for 34 Motors,9 Gates and 3 Hot Water Valves for Operation

Automatic Mode (Via PLC).

Supply PLC panel (VIPA PLC) for controlling the Process Algorithm. Design PLC application for the process.

Design SCADA system (MOVICON) for controlling and monitoring the process. Design Connection wiring.

Install Ducts and cable trays for power and control Cables. Pulling, laying and termination of power and control cables.

Connection of Power Panel and control panels.

Install Valves and Gates Mechanically in the Field.

Wiring and Connection of the Components and instruments in the field.

Commissioning and start up for the overall system.

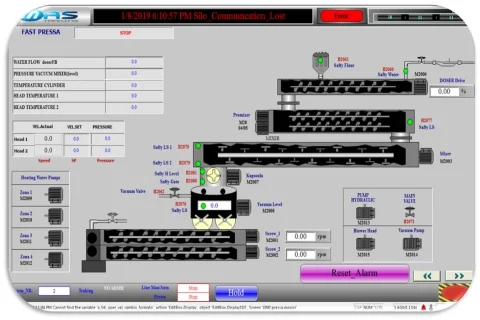

East Delta Pasta

Automatic Mode Via PLC

Supply PLC panel (VIPA PLC) for controlling the Process Algorithm. Design PLC application for the process.

Design SCADA system (MOVICON) for controlling and monitoring the process. Design Connection wiring.

Install Ducts and cable trays for power and control Cables. Pulling, laying and termination of power and control cables.

Connection of Power Panel and control panels.

Install Valves and Gates Mechanically in the Field.

Wiring and Connection of the Components and instruments in the field.

Commissioning and start up for the overall system.